100 Years, 1913-2013

_ One hundred years ago, building automobiles was a slow process—workers moved from car to car. Building a car using “station assembly” took more than 12 man-hours!

But Model Ts were selling so fast that Henry Ford had to find a way to speed up production.

Moving assembly lines were sometimes used to make simple products such as tin cans. But a tin can has three parts. A Model T has three thousand! Could Henry’s team make it work?

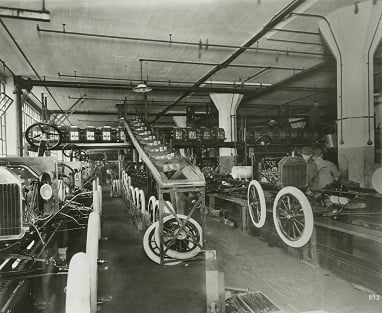

They could. At the Highland Park Plant in 1913, streams of parts first began to converge into a river of automobiles that never stopped flowing. Now the cars moved past the workers.

A year later, it took only one and a half man-hours to build a car. The cars cost less to build, so they cost less to buy, so more people bought them.

What happened at the Highland Park Ford Plant changed the world. Celebrate the massive impact of the moving assembly line with driving tours, lectures, exhibits, and other events.